Plastics Tooling

Mold Materials

EDRO offers tool steels, copper alloys, and aluminum for plastic injection mold, plastic extrusion, rubber mold, and blow mold tooling. Providing tailored solutions to optimize your tool performance.

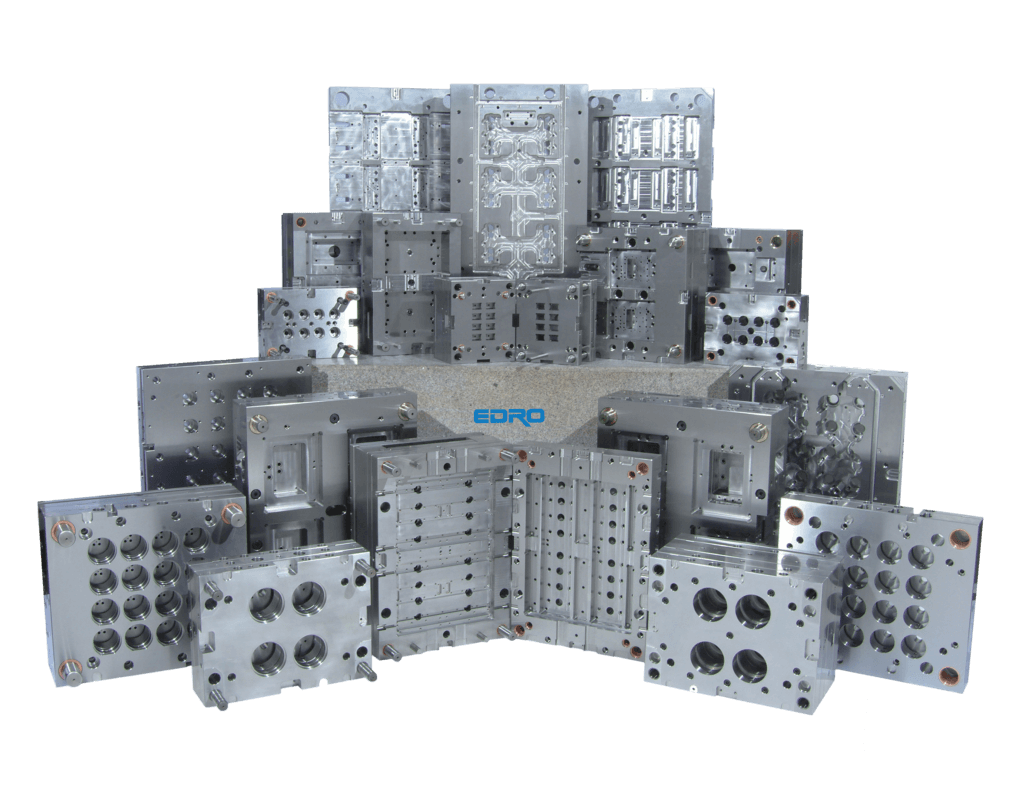

CUSTOM MOLD BASES

EDRO specializes in manufacturing high cavitation custom mold bases, designed to demonstrate precision alignment and long lasting performance. EDRO regularly produces high cavitation stripper plate, stack, double-stack and hot-runner bases, as well as auto unwind and runnerless mold bases to exacting tolerances.

PVD/DLC COATINGS

The EDRO-eifeler coating center in California offers the full voestalpine eifeler PVD/DLC coating portfolio, plus cleaning, polishing, blasting and de-coating services for different types of applications to improve the quality, functionality, efficiency, and durability of tools and components.

ADDITIVE SOLUTIONS

We offer a variety of build technologies such as direct metal laser sintering and direct metal deposition. Capability to print a variety of steels and super alloys, from producing single prototypes to serial production. Post processing capabilities such as machining, grinding, polishing, heat treatment as well as coatings.

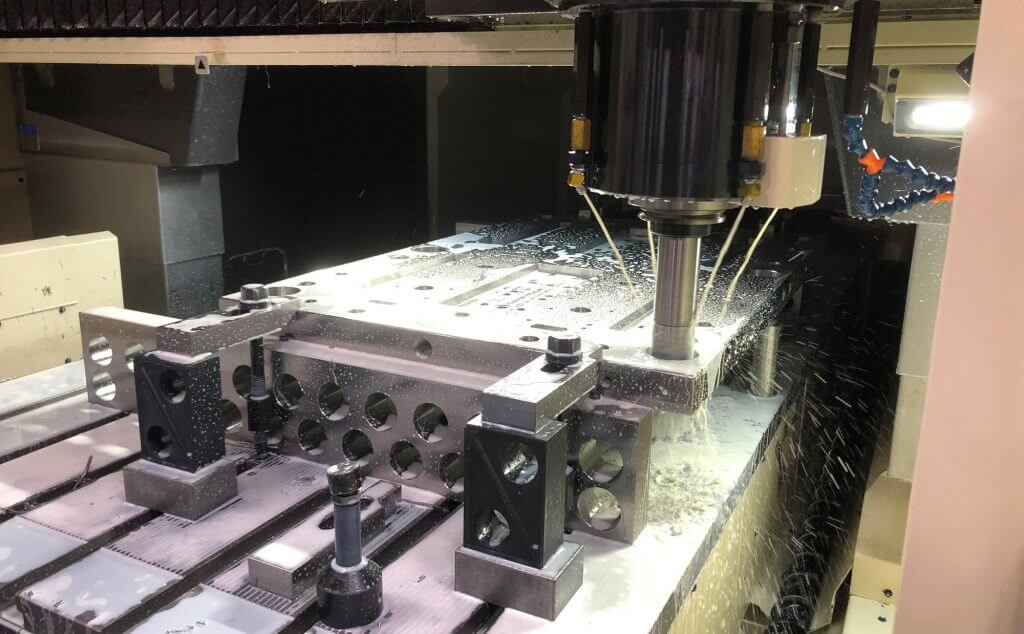

MACHINING SERVICES

EDRO provides machining services to support your tooling applications. We provide quick turnarounds on saw cut pieces and 6 side processed plates. Our gun drilling department is a specialized process designed to drill holes with a high depth to diameter ratio. We utilize top of the line machining centers and specialize in holding tight tolerances with excellent surface finishes. Our surface grinding department can handle larger plate capacities with tight tolerances on flat and parallel.

Our Services

- Custom Mold Bases

- PVD/DLC Coatings

- Aerospace Precision Manufacturing

- Additive Manufacturing

- Machining Services

- Technical Service